Custom Plastic Extrusion Manufacturers Fundamentals Explained

Wiki Article

Plastic Extrusion Profiles Fundamentals Explained

Table of ContentsThe Of Custom Extrusion ManufacturerThe Definitive Guide for Extrusion Of PlasticsThe Best Guide To Plastic Extruded ProfilesThe Best Strategy To Use For Plastic Extrusion ProfilesNot known Details About Plastic Extrusion Profiles

We can also supply custom-made laminations as well as would be satisfied to send you samples upon demand. We presently have 7 lamination stations that can manage various kinds of personalized plastic extrusions. We use customized product packaging as well as are currently packaging an extruded profile product that is offered to a "Large Box" Company.Be it easy, complicated, hollow, coextruded, or embossed, our group of specialists can customize it for you. In addition, our specialists comprehend that no 2 tasks are the same and also we intend to maintain it that way. This implies that below at Keller Products we can use you any type of variety of items for your layout requires.

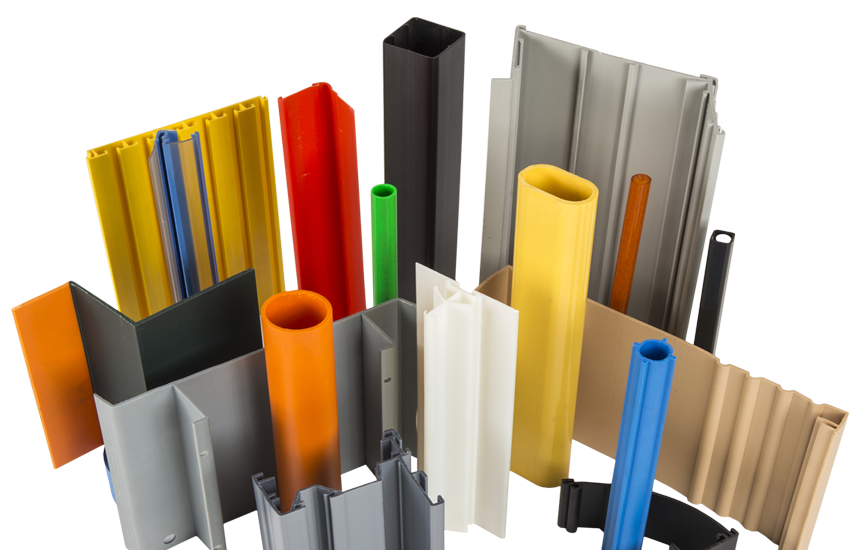

Customized extrusions are custom-made items that are produced by requiring raw products with a die or mold and mildew. This process is understood as extrusion. Extrusion is used to produce objects of a taken care of cross-sectional profile, such as pipelines, tubing, as well as rods. The raw material, known as the "extrudate", is very first softened by home heating.

Extrusion can be utilized to develop items from a variety of materials, including steels, plastics, and compounds. It is used in a selection of markets, consisting of automobile, building, and also manufacturing.

All About Plastic Extrusion Profiles

There are numerous firms that sell this sort of production. These business can help you to make the best item for your demands and also then create it utilizing the extrusion process. If you have a demand for personalized products, customized extrusion related handling may be the excellent remedy. Prototyping your next vital project can be as very easy as contacting Alpha Personalized Extrusions, Inc.Furthermore, Alpha Personalized Extrusions, Inc. provides a host of secondary capacities to complete your total task. Call today!.

Include hinges, seals, top layers, numerous colors and other functions

The Basic Principles Of Plastic Extrusion Companies

Our receipt of your acquisition order starts the scheduling process. What is the standard lead time for a manufacturing order? The characteristics of custom-made manufacturing commonly result in fast modifications to tooling, production as well as manufacture timetables.

We can generate a more accurate quote if we can reference a Pantone shade number. If no Pantone number is available, anything can be custom color matched. For how long does a personalized color suit take? It typically takes 10 functioning days to obtain a color chip to you for approval, as well as 10 added functioning days to create the custom-made color concentrate from the approved shade chip.

What is the maximum possible size of an account? The extrudable account is determined by gauging its established width.

The Best Strategy To Use For Extruded Plastic Profiles

We have actually been doing it right since 1962 and are confident that your job will benefit from our extensive experience in:. plastic extrusion manufacturers. https://www.businessmerits.com/author/k3ll3rpl4st8/.NCS likewise provides co-extruded materials of different durometers as well as different materials that are co-extruded right into the exact same component. If you have inquiries concerning co-extrusions or any of our extruded plastic products, please get to out to our group to learn a lot more - custom plastic profiles.

Extruded plastic forms are produced using a high-volume manufacturing process where raw plastic resin product is melted, then compelled via a die to develop a continual account. To develop plastic extruded shapes, the material is positioned into the barrel of link an extruder after that slowly melted. Warmth and also pressure is then made use of to compel the molten plastic into a die.

Little Known Questions About Plastic Extrusion Manufacturers.

With just a small change, extrusion molding can go from producing intricate forms to plastic sheets. After plastic leaves the extruder, it remains warm as well as can be further manipulated. This permits producers to alter the form of extruded plastic utilizing rollers, footwear, or dies to satisfy the certain requirements of several applications.Extruded plastics are utilized throughout commercial and also commercial applications, with a few of one of the most usual being tubes, rods, and specialized accounts. Applications for extruded plastic tubes, rods, and specialty profiles consist of:.

Ask us to solve your issues and also rely upon us for precision and on-time shipment.

At Astro Plastics, our period in the sector as well as array of top-end capabilities enable us to supply on even one of the most complicated customer request. Our group of experts works very closely with you to tackle your custom-made plastic extrusion requires from concept to completion, making certain you get the appropriate product at the correct time.

Report this wiki page